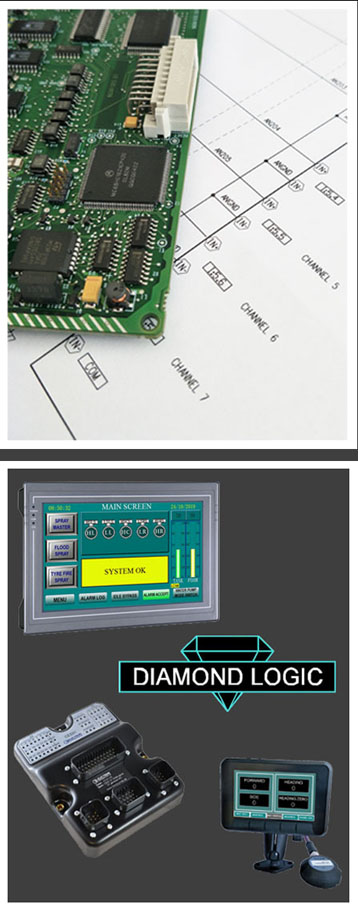

We recognised the need to simplify electrical drawings to assist the diagnostic speed of maintenance personnel.

This has led to a unique drawing style that was created and developed solely by CAED Pty Ltd.

* ‘As Built’ - We will create the “As Built” documentation containing modifications made to the equipment of Original Equipment Manufacturers (OEM).

* OEM Documentation - As part of this service we are requested to re-interpret and simplify the original OEM documents to increase system comprehension.

* Fault Finding Made Easy - Our drawing style is easy to understand and follow and as such is widely used as a drawing standard for mobile mining equipment in the Hunter Valley and Australia wide.

* Reduced equipment down time – A reduction in time taken to understand and follow an electrical circuit is a reduction in time taken to diagnose a problem. Time is money!

* NAS Vault – Pdf files of Client drawings are transferred into the NAS Vault storage facility which is accessed via the CAED® ‘Client Login’ portal.

This is a free service and is Username & Password secured.

Clients can view, copy and download any files stored via all devices, anytime, any location.

This greatly benefits users out in the field.

* Professional presentation – we supply to our Customer requirements.

Examples are:

* Electronic format.

* Printed onto A3 water/tear proof paper and bound into a hard, durable folder.

* Supply copies of files onto a USB.

* Printed & spiral bound.

CAED Pty Ltd is a company built on many years of Electrical, Instrumentation and Controls experience that was gained within the Mining and Industrial sectors.

We offer a host of Signature mobile equipment control systems, modules & sensors for use in a variety of applications.

Product development is under our other trademarked company Diamond Logic.

Whether providing single components or entire systems, our goal is to innovate and offer customised solutions for our clients to bridge the gap between concept and production.

We can cater for small “one off” prototype projects through to systems that are produced in large numbers.

We have installed our control systems on:

* Drills * Dozers * Trucks * Loaders

* Graders * Backhoes * Water Carts * Service Trucks

* Rubber Tyre Dozers

Typical applications that can be combined into a single unit are:

* Idle Timer Control * Autolube Control * Drill Depth systems

* Pipe In Hole * Ladder Control * Machine Monitoring & Shutdown

All wiring is connected to a single unit (less harnessing, cheaper installation).

No flashing code lights, all warnings and indications are displayed graphically in a Touchscreen.